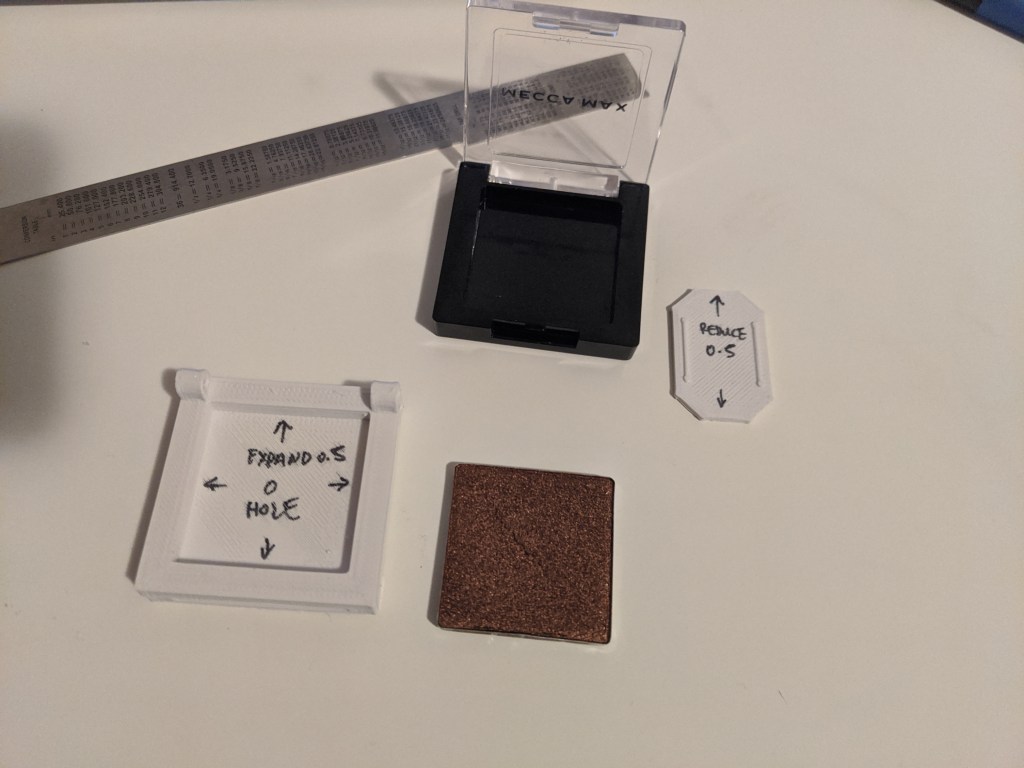

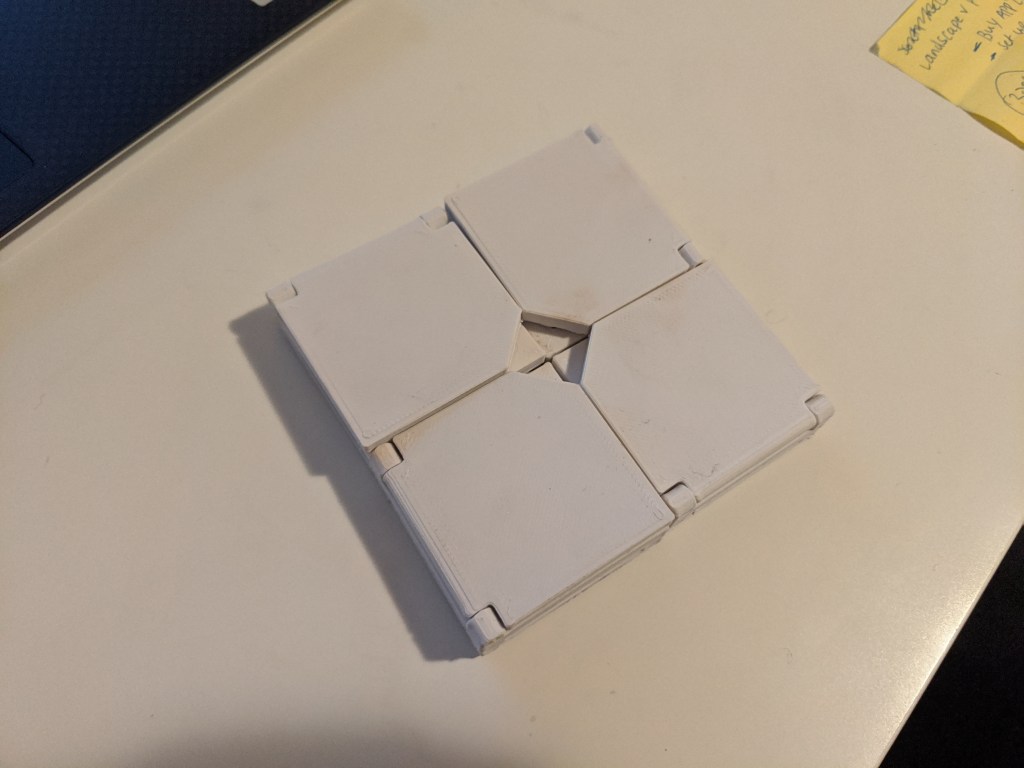

Part 1 Single shadows and DIY palettes

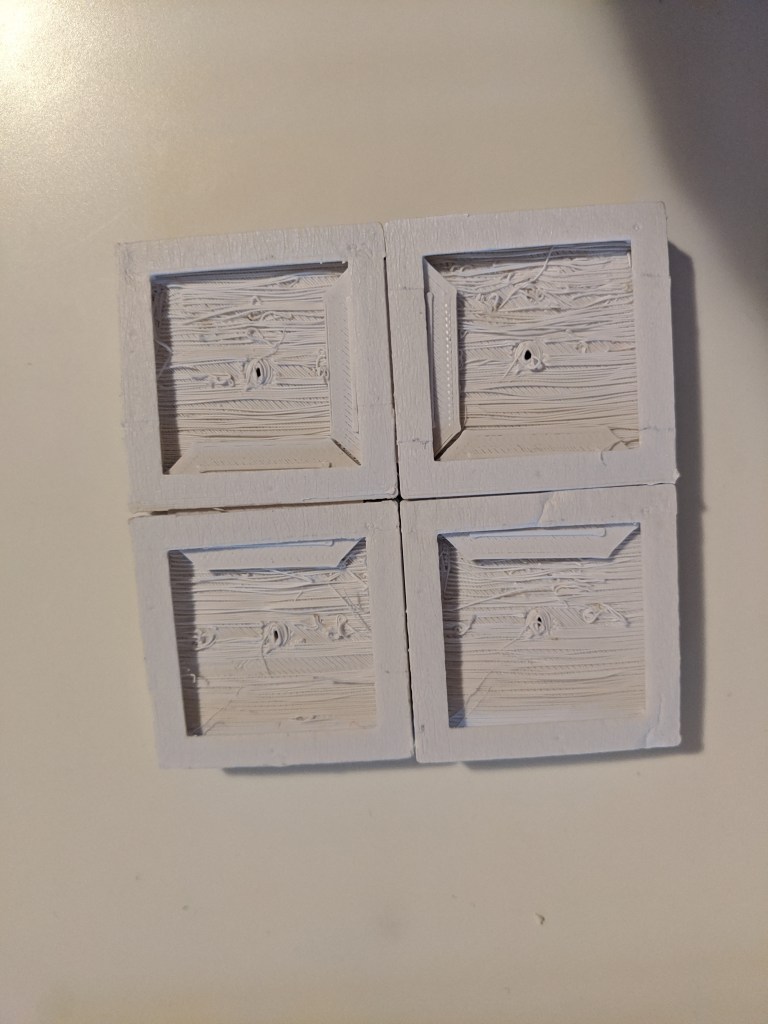

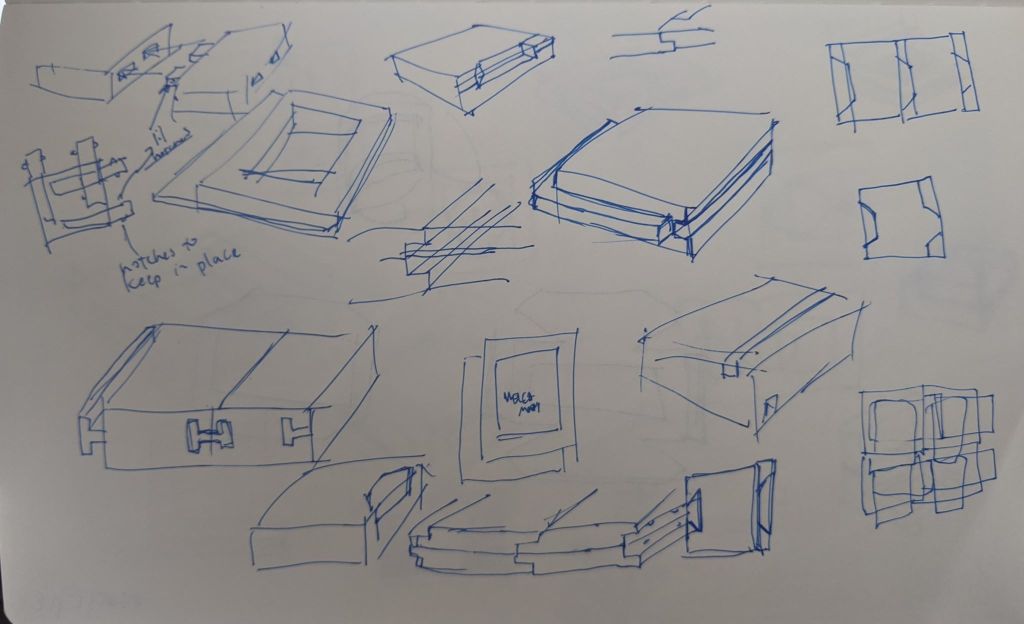

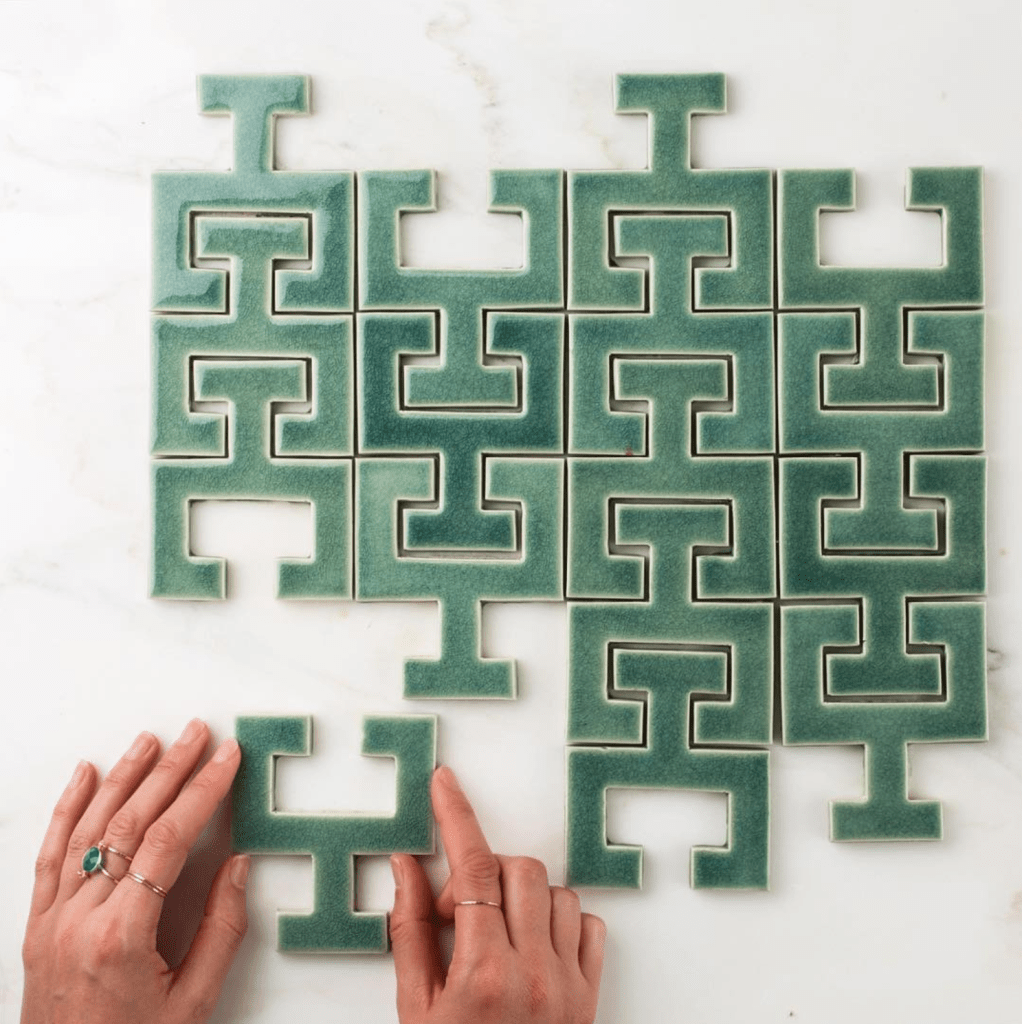

Part 2 Lego makeup and tiles

Part 3 Cracking eggs to make an omelette

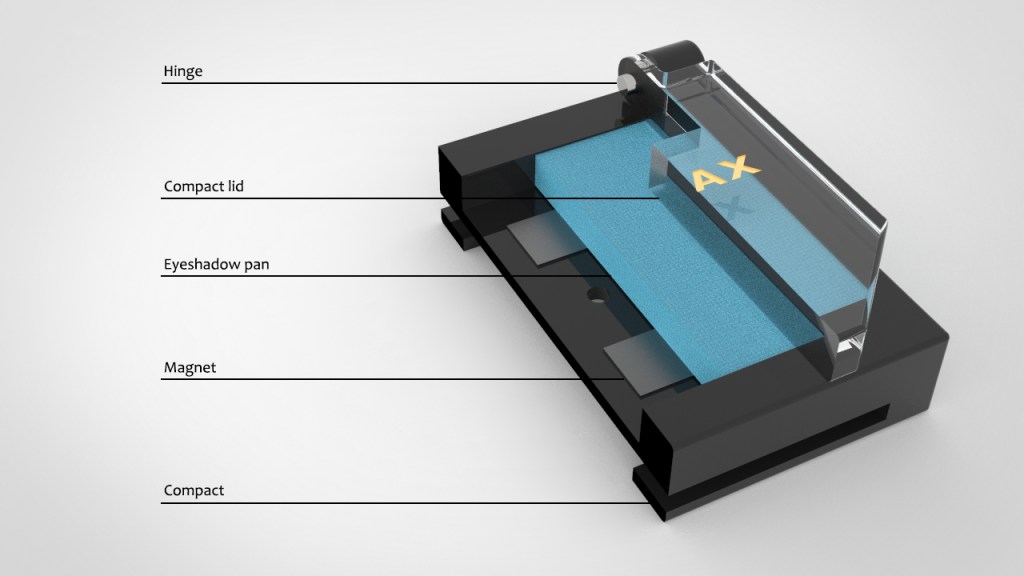

They say a picture says a 1000 words, right? That good hero shots won’t require numerous renders? And by the end there won’t be many questions? Hopefully? FYI the shades used for the shadows in the renders are actual colours from the MECCA MAX single shadow range!

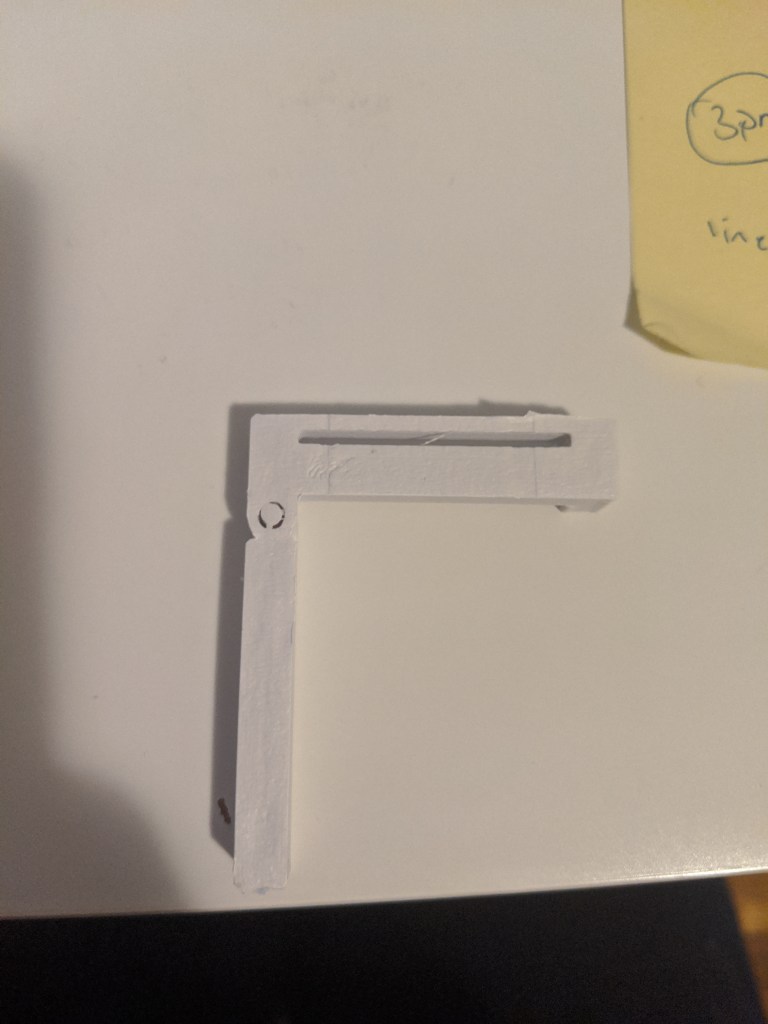

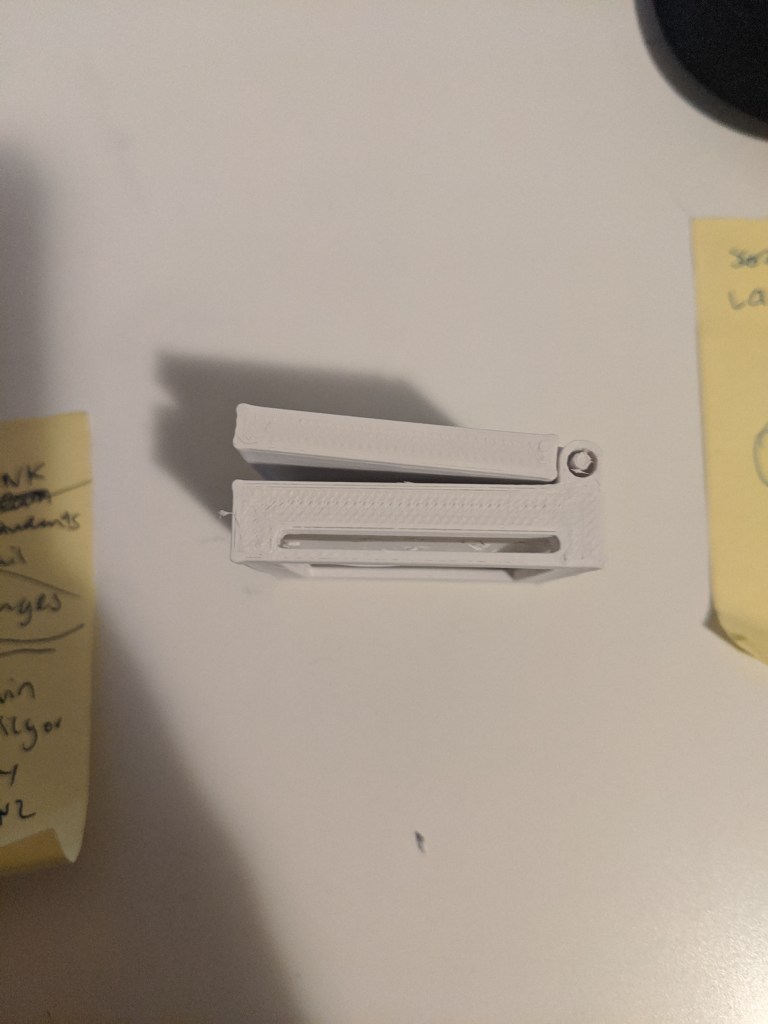

* So one of my main concerns was using more plastic to create the connectors. Sustainability is a growing concern in the beauty industry because there is so much waste and the industry is so large. Waste can come from the packaging the product comes in, fancy wrapping material to “enhance the experience”, PR packages sent out to influencers and the main one: products typically aren’t refillable so you’re constantly chucking out empty products to purchase a new one. I have seen more people try and upcycle their empty containers but there’s only so many empty jars and bottles that we can turn into succulent pots and vases.

More companies are using recycled and recyclable plastics. One of my favourite brands that does this is REN Skincare, they have pledged to become Zero Waste by 2021 meaning all of their packaging will be 100% recycled, recyclable and reusable ♪┏(・o・)┛♪┗ ( ・o・) ┓♪ (happy dance).

MECCA uses a program called TerraCycle which collects and recycles hard-to-recycle waste. MECCA has Beauty Products Zero Waste Boxes located in some of their stores so you can bring your empties in to recycle when you go in store to repurchase your products, which I think is pretty neat. However, while this is a great program it’s not advertised very well and I don’t think many customers know about it. MECCA also readily and happily provides samples in little sample pots for customers to try products before they commit to the full size. It’s part of their amazing customer service (if I may say so myself) but again, it creates so much waste. I’ve seen some people with baskets full of these sample pots, I did a quick look around my room and this is how many I had.

So going back to modular eyeshadows, I think it would be great if we could recycle the sample pots and use that plastic to create the connector tabs. We could do this locally as well by utilising the Precious Plastics system which is another great way to recycle plastics!

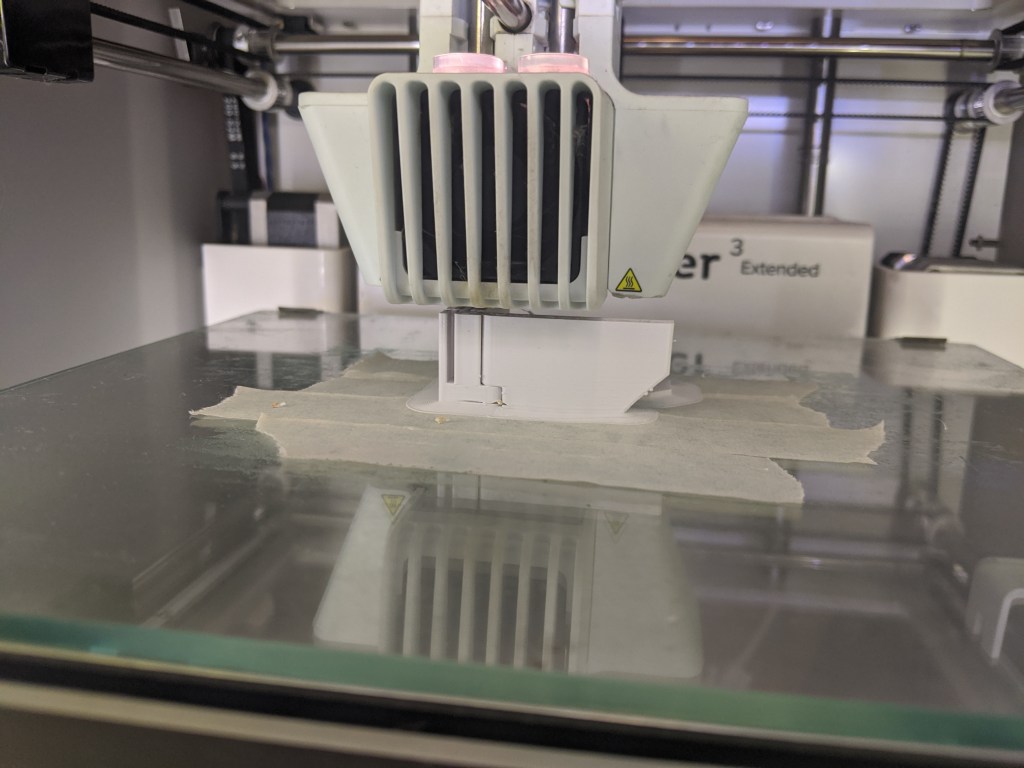

It’s been a long minute since I used KeyShot for rendering products but I think I did okay. I never actually really learnt how to use KeyShot properly or to it’s full potential but am hoping to learn more through these projects I do. This post turned out to be longer than I expected, just got a little too into talking about plastic. Next post will be about manufacturing and tooling design which will probably be a long one.

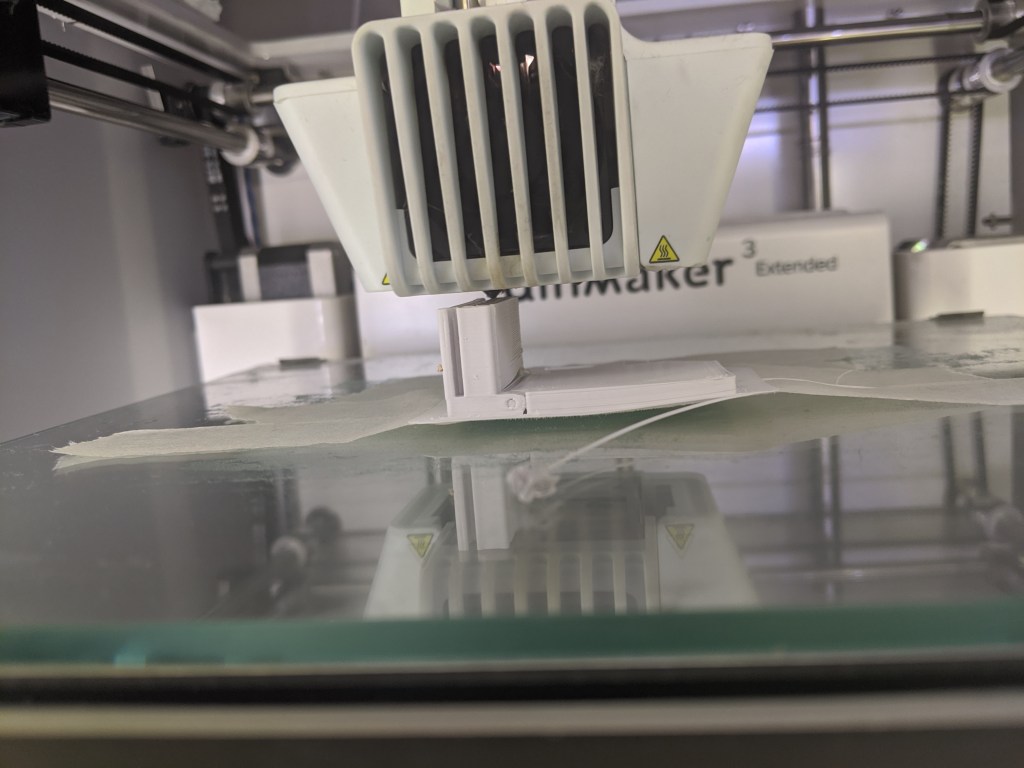

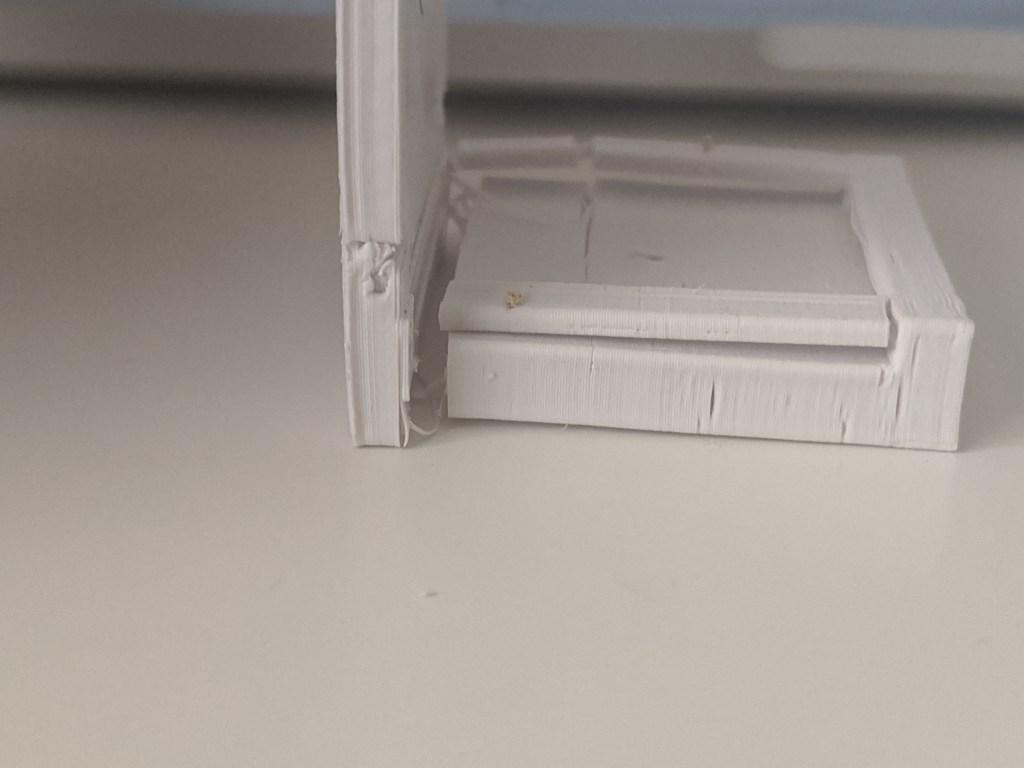

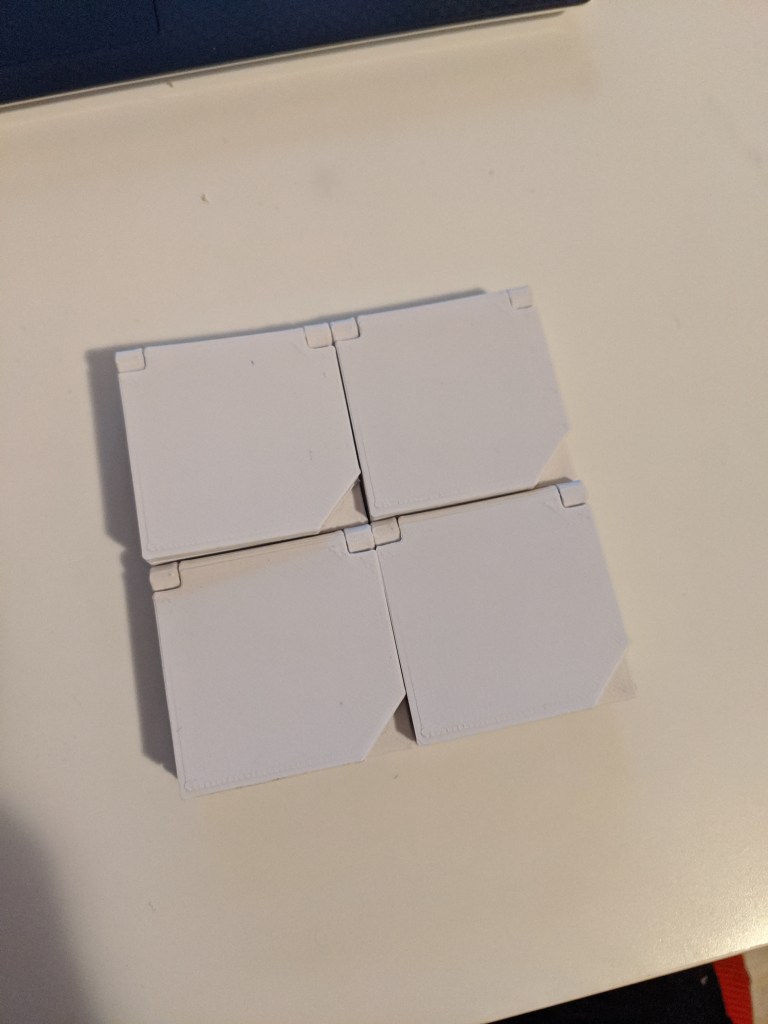

Bonus pics:

Original https://www.instagram.com/p/CC-dQXgjyCp/

An okay attempt

Anyway after all these renders, I realised there is a problem with the compact. Can you spot it? It’s not the uncentered MECCA MAX logo which is also annoying me.